Mains / Line Frequency Transformers

This describes the theory and answers common questions on Mains Voltage (50Hz/60Hz) Transformers

1 Testing Line Frequency Transformers

Transformers appear in almost every electrical and electronic product that the world produces providing the world with an enormous need for transformers.

Testing transformers and wound components is essential before final assembly into product.

This filters out failures ahead of time, avoids costly re working, reduces manufacturing costs and improves overall reliability.

Transformer testing thus requires:

Fast effective quality controlled manufacturing methods

100% testing securing zero rejects sent to the customer

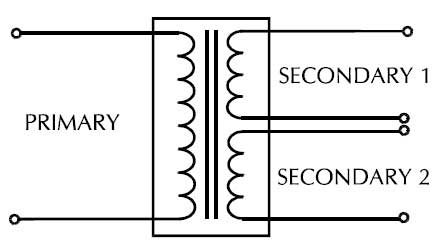

Laminate transformers are mostly used as line frequency, low frequency and low/high voltage step-up, step-down transformers.Two coils are wound over a core such that they are magnetically coupled. The two coils are known as the primary and the secondary.

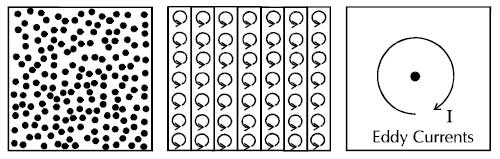

The core material tends to be constructed from thin sheets of a soft magnetic material (approx. 0.35 mm thick), usually made of 4% silicon steel, called laminations, these are insulated from each other by varnish. These thin sheets reduce eddy currents by increasing the resistance to the flow of such loss-causing currents.

Eddy currents are one of the two main elements associated with overall core losses. The second, Hysteresis Loss, is the energy used up by changing the magnetic state of the core during each cycle and eddy currents are currents induced in the core by time varying fluxes.

The core is partially assembled prior to the windings being inserted and once inserted the remaining laminate sheets are then interleaved to avoid all of the joints coming into one place, the joints are then staggered similar to laying bricks.

Laminate transformers are used in most low frequency applications usually between 50Hz and 400 Hz. The primary tends to have a high inductance this allows low frequency use with minimal core losses. Laminate transformers provide the following:

High voltage step-up.

Low voltage step-down.

High current output.

Isolation.

For the purpose of this document we will concentrate on a step-down laminate transformers. By designing the number of turns in the primary and secondary windings, any desired step-up or step-down transformer can be realized.

The coupling between the primary and secondary must be tight in a power transformer in order to reduce the leakage reactance, otherwise the drop in reactance will be considerable and will vary with secondary voltage and current.Therefore laminate transformers are wound with concentric windings (the primary and secondary are wound with half the turns onto the core limb, one over the other (to give a close coupling) with intervening insulation.

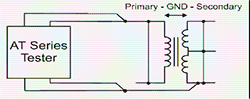

Voltech transformer testers combine virtually all tests into one box resulting in fast test time avoiding re configuration for each test.

2 Critical Transformer Tests for Line Frequency Transformers

|

Test Parameter |

Critical for |

Tester essentials |

| Magnetizing current (MAGI) | Check transformer has been assembled properly, with the appropriate number of turns, the right grade of magnetic material for the core, and the correct air gap if required. |

Check primary turns and correct core material properly assembled |

| Resistance (R) | Check for the correct wire and good solder termination | DCR is the direct current (DC) resistance offered by an inductor due to the resistance of the winding. Expressed in ohms or milli-ohms maximum. |

| Wattage (WATT) | Core loss measurement to confirm that the transformer has been assembled properly | Measured power is the power dissipated by eddy current and hysteresis effects in the core and is known as the core loss  |

| Hi-pot (HPAC) | Ensures that the windings are positioned correctly with the correct materials to provide the required level of safety isolation. | Measures and controls the applied voltage throughout the complete duration of the test. The AT3600 applies a voltage between two groups of windings (or core) with the windings in each group being shorted together.  |

| SURGE (SURG) |

Check shorted turns. Ensures that the insulation material |

A high energy impulse is discharged into a winding. The transformer is characterized by the area under the waveform, measured in volt-seconds. |

| Insulation Resistance (IR) | Check the integrity of the insulation between separate windings, or between a winding and a core or screen. |

Tester applies a dc voltage between two groups of windings with the windings in each group being shorted together. |

| MAGX, VOCX, WATX, STRX | Extend test range with AC interface |  |

3 Transformer Basics

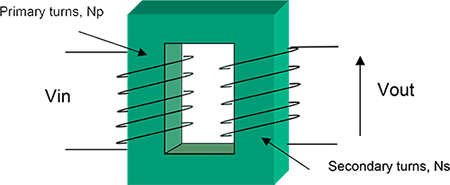

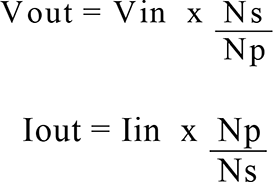

An alternating voltage, Vin applied to the primary creates an alternating current Iin in the primary winding.

The current produces an alternating magnetic flux in the core.

The alternating magnetic flux generates a voltage, Vout, in the secondary

For sine-waves, the flux density, B = Vin / ( 4.44 N A f) where

N = Number of turns

A is the cross sectional area of the core

f is frequency.

Since for a given transformer, B, A and f are constant: -

Transformers

Step up or step down ac voltage

Step up or step down ac current

Because there is no electrical connection between the primary and secondary windings they provide isolation from one electrical circuit to another.

It is these unique properties of transformers that make them so widely used in all kinds of electrical / electronic equipment.

4 Transformer cores

Core power losses comprise,

a) the hysteresis losses from magnetising and demagnetising the core through the BH loop,

b) plus any additional eddy current losses

Cross Section of: Ferrite, Laminated, Solid Core

In a solid core, current can circulate inside the core material generating I2R (resistive) losses.

Iron cores are usually laminated to restrict the current path and reduce this effect.

Ferrite cores have even higher resistance and hence very low eddy current losses.

5 Transformer Equivalent Circuit

An Ideal Transformer has:

- No losses.

- Perfect coupling between windings.

- Infinite open circuit impedance (No load current = 0 ).

- Infinite isolation between windings.

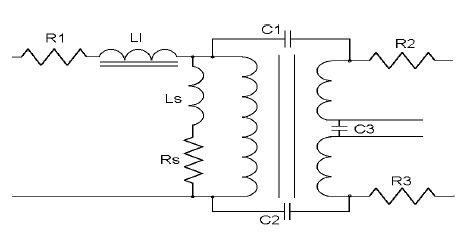

In reality, practical transformers show characteristics that differ from those of an ideal transformer.

Many of these characteristics can be represented by a transformer equivalent circuit.

Real Transformer Equivalent Circuit

In the transformer equivalent circuit for the "real life" case

Ls and Rs are used to model the effect of core losses.

R1, R2, R3 are the resistances of the windings.

Ll is the leakage inductance.

C1, C2 and C3 are the inter-winding capacitances

7 Essential Capability

The Voltech AT testers have the built-in capability described below.

|

Capability: |

AT5600 + AT3600 |

ATi |

| 20 way switching matrix | Yes | Yes |

| PC test editor and results server | Yes | Yes |

| Quick-change Fixture System | Yes | Yes |

| Test fixture system | Yes | Yes |

| Small signal tests (e.g. inductance, capacitance, turns ratio) | Yes | Yes |

| Telecoms. tests (e.g. return loss, longitudinal balance) | Yes | Yes |

| Insulation resistance | 7000 V | 500 |

| Hi-pot (AC) | 5000 V | NO |

| Hi-pot (DC) | 7000 V | NO |

| Magnetising current and open circuit voltage | 270V | NO |

| Watts, Stress Watts | 25 W | NO |

| Leakage Current | 2 A | NO |

To make use of this capability, the testers may be fitted with a number of different tests such as inductance, ac resistance, turns ratio, watts or ac hi-pot.

Tests are sold in packages such as Standard or Gold or may be purchased individually and fitted by the user via firmware upgrade.

8 Extended Capability

External AC Power (AT5600 + AT3600) - Flexible power source for larger transformers.

The ATs programmable internal ac source may be used to provide up to 270V at 2 A RMS from 20 Hz to 1500 Hz.

This supply is used for measuring magnetizing current, watts and open-circuit voltages on iron laminate transformers.

The tests are usually made with the transformer off load or open circuit such that transformers rated at 2 kVA or more may be tested.

This internal ac source has several advantages, perhaps the most important being the ability to ramp up the voltage and current under real time software control to minimize inrush current and test time.

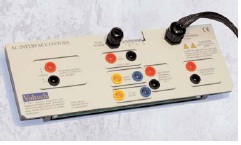

The Voltech AC Interface allows external AC sources (including simple step-up or step-down transformers) to provide extended AC power seamlessly within the AT test environment.

With the AC Interface, the AT capability may be extended up to 600V at 10A RMS

External AC Sources that may be integrated into the AT3600 test environment include:

Simple step up transformers (providing up to 600V @ 0.8 A)

Simple step-down transformers (providing up to 10A @ 20 V)

Fully programmable external ac sources (providing up to 600V @ 10A).

Tests for the AT3600 + AT5600 with the AC Interface

| MAGX | Magnetising Current (External Source) | 50 mA to 10A | 5 V to 600 V | 20 Hz to 5 kHz | 0.1% |

| VOCX | O/C Voltage (External Source) | 100 mV to 650 V | 1 V to 600 V | 20 Hz to 5 kHz | 0.1% |

| WATX | Wattage (External Source) | 1 mW to 6 kW | 5 V to 600 V | 20 Hz to 5 kHz | 0.3% |

| STRX | Stress Wattage (External Source) | 1 mW to 6 kW | 5 V to 600 V | 20 Hz to 5 kHz | 0.3% |

9 External DC Bias - Real Saturation Test Conditions for Power Transformers and Chokes

Power transformers and chokes that carry a high dc current are common in power supplies and inverters. Testing these parts at their rated dc current provides complete confidence that the parts have been correctly wound, assembled and terminated.

The Voltech DC1000 25A dc current supply will seamlessly integrate into the AT3600 or ATi test environment to provide up to 250 A (10 x DC1000 in parallel) of smooth, programmable dc bias current with minimal effect on the ac inductance measurement.

25 Amps programmable dc current

250 Amps with 10 x DC1000

Works seamlessly with AT3600 or ATi

Unique electronic inductor design minimizes effect on the ac inductance measurement

Can be used on almost any LCR meter. Alternative for Agilent, Wayne Kerr and Chroma types.

Tests for the DC1000 and AT3600/ AT5600 / ATi

| LSBX | Inductance with External Bias (Series) | 1 nH to 1 MH | 1 mV to 5V | 20 Hz to 3 MHz | 0.5% |

| LPBX | Inductance with External Bias (Parallel) | 1 nH to 1 MH | 1 mV to 5V | 20 Hz to 3 MHz | 0.5% |

| ZBX | Impedance with external bias | 1 mΩ to 1 MΩ | 1 mV to 5V | 20 Hz to 3MHz | 0.2% |