Hi-Pot Testing for Transformers

Guide to AC and DC High Voltage Safety Testing

INTRODUCTION

Transformers are essential components in electrical systems, operating on the principle of inductance. They enable accurate voltage transformation with excellent isolation, thanks to their design that separates windings physically. Despite being a mature technology, transformers are still widely used due to their reliability, efficiency, and ease of manufacture.

Ensuring long-term safety and reliability requires rigorous testing, especially to verify the isolation between windings. One of the most critical tests is the Hi-Pot (High Potential) test, which checks for insulation integrity by applying a high voltage to the transformer. This article delves into the AC and DC Hi-Pot testing methodologies, industry standards, and frequently asked questions to help you understand the best practices in transformer safety testing.

Hi-Pot Testing - How and Why?

Despite being a mature technology transformers are still widely used, due to the unique combination of three properties ;

1) Accurate Voltage transformation.

2) No active or solid state parts - easy to manufacture.

3) Excellent isolation due to physical separation of windings.

Hi-Pot testing is essential for identifying insulation faults that are invisible during standard low-voltage (0-240V) testing. These faults could be due to mechanical defects like voids, cracks in winding wire enamel, or other insulation breakdowns caused during manufacturing, transport, or handling.

Hi-Pot testing is performed to ensure that transformers can withstand voltage spikes, inrush currents, and environmental changes like temperature and humidity, which can degrade insulation over time. Unlike low-voltage tests, Hi-Pot tests subject each transformer to voltages much higher than its normal operating voltage, ensuring long-term safety and performance.

Determining the Hi-Pot Test Voltage

Hi-Pot testing is conducted during both the design phase and production phase:

-

Design Phase: To verify the suitability of materials and design before mass production.

-

Production Phase: To ensure consistency in manufacturing processes.

Industry standards typically require testing transformers at twice their operating voltage plus an additional 1000V for safety.

For example, a transformer designed for 240V would be tested at:

Hi-Pot Test Voltage = (2 x 240V) + 1000V = 1480V

This margin ensures that the transformer can handle transient spikes and aging effects.

Industry Standards for Hi-Pot Testing

Historically, transformer testing was guided by separate standards such as:

-

IEC 60950: Information technology equipment safety.

-

IEC 60065: Audio, video, and similar electronic apparatus safety.

However, these have been superseded by the IEC 62368 standard, which combines safety protocols for audio, video, and IT equipment. The newer standard emphasizes safety across all components, including transformers, making Hi-Pot testing even more critical in the supply chain.

How is a Hi-Pot test Performed ?

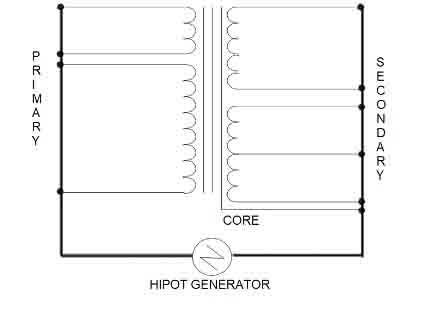

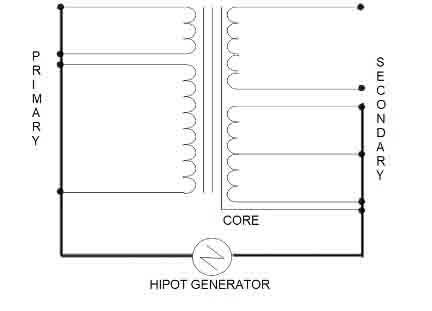

A HIPOT test is performed by applying a high voltage signal between a chosen shorted HI side to a shorted LO side of the transformer as shown in the diagram below.

Test Procedure:

- Apply High Voltage: A voltage is applied between the high (HI) and low (LO) sides of the transformer.

- Dwell Time: The voltage is maintained for a specified time (referred to as DWELL time) to detect potential insulation breakdown.

- Current Measurement: If the measured current exceeds a predefined limit, the transformer fails the test.

Failure Modes:

- Flashover: A sudden, catastrophic failure detected by a hardware trip circuit, usually indicated by a visible spark or audible crack.

- Measurement Failure: If the transformer maintains stable conditions but the current exceeds the limit, it is classified as a measurement failure.

AC vs. DC Hi-Pot Testing: Which is Better?

The choice between AC Hi-Pot and DC Hi-Pot testing depends on industry standards and specific customer requirements.

HPAC (AC Hi-Pot Testing):

- Voltage Range: 0-5 KV AC, 50-1000 Hz.

- Pros: Faster ramp-up time and quicker charge decay.

- Cons: Current measurement includes capacitive effects.

HPDC (DC Hi-Pot Testing):

- Voltage Range: 0-7 KV DC.

- Pros: Provides a clear indication of resistive current flow, eliminating AC effects.

- Cons: Longer ramp-up time due to transformer capacitance.

Both HPAC and HPDC tests on the Voltech AT5600 automatically discharge residual charges, ensuring safety.

AT5600 HIPOT Testing Best Practices

To optimize Hi-Pot testing with the Voltech AT5600, consider the following best practices:

Ramp up time

The speed at which the large test voltage is applied should be considered so that the maximum is achieved under stable control.

This is especially true of larger test parts (e.g. toroidal transformers or E-core laminates), where a ramp up time of 0.5-2.0 seconds may be needed depending on the size and capacitance of the transformer.

Avoid Floating Nodes

For best practice, all terminals in the component should be selected as either HIGH or LOW to avoid any windings to float.

Unconnected terminals or nodes will tend to float to an uncontrolled potential, somewhere between the 0V Low and the energized HIGH voltage.

This is undesirable from a measurement point of view as this uncontrolled winding can affect the stability of the already very small current measurement being made between the chosen terminals.

It is also undesirable from a test safety point and unit protection of view as floating windings can remain charged after the test is completed. Again this is especially true for physically larger transformers.

This charge could then possibly affect later low voltage tests on those floating windings or at worst cause an accidental discharge into the AT tester when it attempts to connect the winding for a later test.

AT5600 HIPOT Generator and the IEC Standard

The AT5600 is designed to meet the transformer testing requirements of IEC 62368-1 and IEC 61010-1 and the UL equivalents.

These standards do not require power for production hi-pot testing of the transformers, but only specify the test voltage and duration of test ( also referred to as the “dwell time.”)

The IEC standards allow the test duration to be reduced to 1-2 seconds if the test voltage is increased by 20% above requirement.

This obviously gives a large improvement in test throughput for manufacturers, as long as each of the specific designs can withstand the extra 20% of test voltage.

This would obviously need checking by batch pre-testing to confirm suitability, before fully implementing.

The IEC standard contains derating graphs which explain in more detail the allowed reduction of test time, against the corresponding increase of test voltage needed.

The AT5600 HIPOT Generator has a rating of 250VA.

Even with a winding capacitance as high as 10nF, the required current at 5 kV 60Hz is only 19.1 mA, corresponding to a VA requirement of only 96 VA, so the 250VA has plenty of excess capacity to generate the voltages required for even the largest transformers.

Troubleshooting Hi-Pot Testing Issues - FAQ’s

Q1 ) I tested the same part with two AT5600s, both units read differently for the HPAC/HPDC

Unit 1 - 3.2 uA

Unit 2 - 10.0 uA

The AT5600s do not read the same small current, what should I do?

Answer:

As with any electrical measurement, as the signal tends to zero, the possible error in the reading will increase.

HI-pot measurements, by their very nature, are measuring very small currents.

An ideal transformer would give a HIPOT current reading of zero.

It is a common misconception to think of these measurements as you would a more typical DCR reading of say 2 ohms, where you expect stability and repeatability.

However, since the current is very low, you should expect that such very small readings would be susceptible to the inherent noise floor of the unit.

This could give you a range of readings for different test equipment, but that should still be well below the requirement requirement or your specified limits.

A bad isolation (e.g., dead short, weak enamel between windings etc.) would give you excessive current readings greater than your limits or even a hard flash over / 3400 trip for genuine bad parts.

Some test equipment manufacturers choose to return results below a set number (say 20uA) as a hard “0.00”, but we have chosen to always report a number as proof of measurement, even if such small results may be subject to a large (eg + / - 100%) error tolerance.

It is therefore normal to get slightly different HPAC/HPDC on different AT Units in cases where the part under test is a good isolator, and the current measurement is inherently very small.

Q2 ) My AT5600 gives 3400 error codes even if I reduce the HIPOT requested voltage.

What are the troubleshooting steps to fix this problem?

Answer:

There are things that could be causing the 3400 TRIP on the AT5600.

1, Fixture plate used - the fixture itself could be contaminated, or does not have enough clearance for the voltage stand off required. (a good rule of thumb is at least 1mm minimum per 1000V standoff)

2, A Genuine bad part.

3, Large natural capacitance of the part (for larger transformers - in these cases increase the RAMP UP time).

The trip mechanism on the AT5600 during the HIPOT test engages when a dead short or an excessive current has been measured.

If the trip happens in multiple parts, that you suspect are actually "good", then you should check the fixture being used.

You can quickly test the fixture and unit by the following two tests.

1, Running the program (ideally 4-5 times) and directly from the AT Editor, with the fixture fitted but NO UUT fitted.

You will expect to get failure on the measurement tests (eg, R, LS, RLS, Z, MAGI etc.) as no part is present.However, an HPAC or HPDC tests you have programmed should pass

If the HPAC/HPDC tests fail with no UUT fitted, then the fixture is not properly isolating the nodes.

Examine the fixture for

A, signs of contamination on the top surface.

B, the separation of the wiring within the fixture - wires should not cross over each other, as this can result in “cross-talk”

2, Run the program on the unit with NO fixture, and NO UTT connected.

As above this will test the hipot integrity of the unit

You will expect to get failure on the measurement tests (eg, R, LS, RLS, Z, MAGI etc) as no part is present.

However, an HPAC or HPDC tests you have programmed should pas

If you have a HPAC or HPDC failure with no fixture connected, then please contact us.

Q3 ) My AT5600 Screen suddenly flickers during the HIPOT test, is my unit faulty?

Answer:

Any high voltage test (especially with larger signals as high as 3- 5kV), can result in EMI emissions through the air.

Due to the relative closeness of your UUT to the AT5600 screen, the large screen of the AT5600 could pick-up this energy.

This can cause the screen to flicker during these tests, but is only a visual effect and has no effect on the digital operation of the unit.

As long as the test is still controlled, maintained, and the AT5600 is able to finish the test, this is expected behavior and should not be cause for concern.

Voltech AT5600: Advanced Hi-Pot Testing for Reliable Transformer Safety

The Voltech AT5600 is an advanced transformer tester designed to meet industry standards for Hi-Pot testing. With a high power capacity of 250VA, it can handle even the most demanding transformers with capacitances up to 10nF. The AT5600 supports both AC and DC Hi-Pot tests with intelligent features like automated bleed resistors for safety and fast test throughput.

testing. With a high power capacity of 250VA, it can handle even the most demanding transformers with capacitances up to 10nF. The AT5600 supports both AC and DC Hi-Pot tests with intelligent features like automated bleed resistors for safety and fast test throughput.

By using the AT5600, manufacturers can ensure compliance with IEC standards, reduce testing times, and achieve consistent, reliable results, making it the ideal solution for transformer safety testing