IMPORTANCE AND CHALLENGES OF INDUCTANCE TESTING

Why the Voltech DC1000A is the Only Complete Solution

I. Introduction

II. Inductance Testing for Transformers and Inductors

III. The Real Problem in Inductance Testing: DC Bias, Core Saturation, and False Measurement Data

- Efficiency

- Ripple current

- EMC compliance

- Converter control stability

- Excess heat and long-term reliability

In real-world applications, inductors and transformers are rarely exposed to a pure AC signal.

They operate with a combination of AC and DC current at the same time:

✔ AC current: the alternating component used for energy transfer, switching, or filtering

✔ DC current: the steady-state load current flowing through the winding

When DC current flows through the core, it pushes the magnetic material closer to saturation.

As saturation increases, the core’s effective permeability decreases, resulting in a steep reduction in inductance — often by 80% or more.

This is why inductors that measure, for example, 100 µH may fall 20% once operating at full current, and maybe to as low as 20 µH at twice full current.

However, inductance measured using conventional small-signal AC test methods does not represent how the component performs under real operating conditions, where DC is present.

Risks of Inaccurate Inductance Measurement

× Incorrect inductor or core selection

× Excessive ripple and heat losses

× Operating outside specified design limits

× EMC failures during certification

× Late redesigns in the validation stage

× Field failure and warranty returns

IV. Why Conventional Inductance Test Methods Fail Under DC Bias

1) Small-signal LCR meters only measure at low current

Most LCR meters only test at small-signal levels (typically 100 mA or less), which is enough for basic sorting but not for understanding how the part behaves in a real circuit.

2) General-purpose power supplies make it worse

General-purpose power supplies actually degrade the measurement further. Their large output capacitors shunt the AC test signal, making accurate inductance testing impossible.

To measure inductance accurately under real operating conditions, you need a DC bias source that solves the limitations of all conventional test methods.

That is exactly what the DC1000A provides.

V. DC1000A Precision DC Bias Supply: The Only True Solution for Accurate Inductance Testing

The Voltech DC1000A 25A Precision DC Bias Supply is a dedicated high-accuracy DC bias current source designed specifically for inductors, chokes, and transformer testing.

CONVENTIONAL (GENERAL-PURPOSE) POWER SUPPLY

VOLTECH DC1000A DC BIAS CURRENT SOURCE

| Problems with Conventional (General-Purpose) Power Supplies | DC1000A DC Bias Current Source Solution |

|---|---|

| LCR test signal goes into the output capacitor, not the inductor | No output capacitor - LCR test signal passes directly through the inductor |

| Test current bypasses the inductor | Measures actual inductance |

| Misleading measurement results | Ensures consistent, high-precision test results |

| Hard to detect measurement errors | Purpose-built for DC bias testing with any LCR meter |

The DC1000A eliminates the output capacitor commonly found on generic power supplies and uses an active constant-current output configuration that electronically isolates the bias source from the DUT, allowing inductance to be measured under realistic circuit conditions with high DC, adjustable output levels, stable performance, and accurate measurement results.

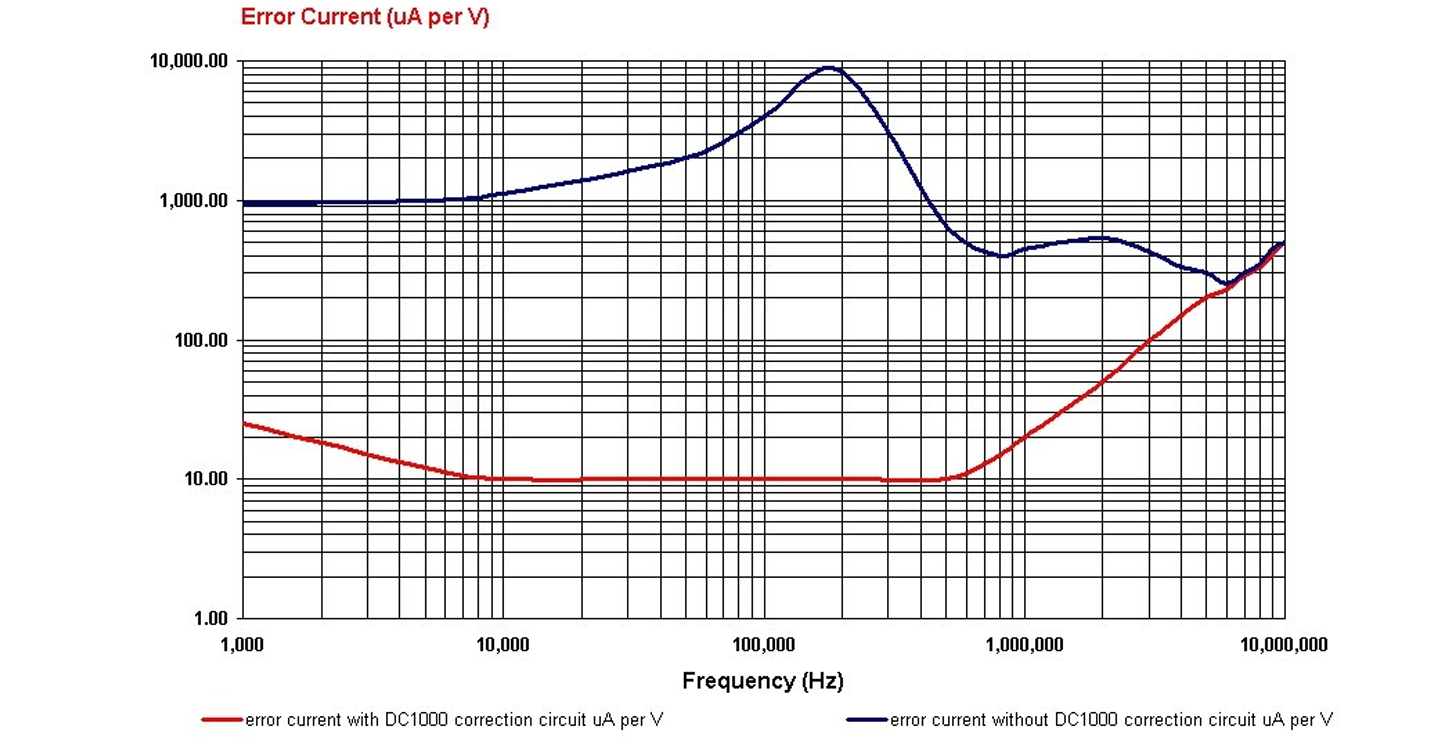

The DC1000A also features proprietary AC correction circuitry that reduces these AC error currents by up to 100×, immediately improving measurement accuracy.

1) Sense Winding Detects Test Signal

2) A high-gain control loop injects AC Signal across the inductor

3) Drives the AC voltage across the inductor towards zero

The graph below shows the significant reduction in error current when the DC1000A’s correction circuit is active.

Advantages of the Voltech DC1000A’s proprietary AC correction circuitry

✔ True inductance under DC Bias

✔ Highly precise measurement results

✔ Full AC test signal integrity

✔ Multi-point inductance-vs-current testing across the operating range

✔ No special interface or modification required for use with any LCR meter

✔ Compact, standalone DC Bias supply

✔ Multiple units can be paralleled easily for higher current (up to 250 A)

✔ Stable and repeatable measurement results

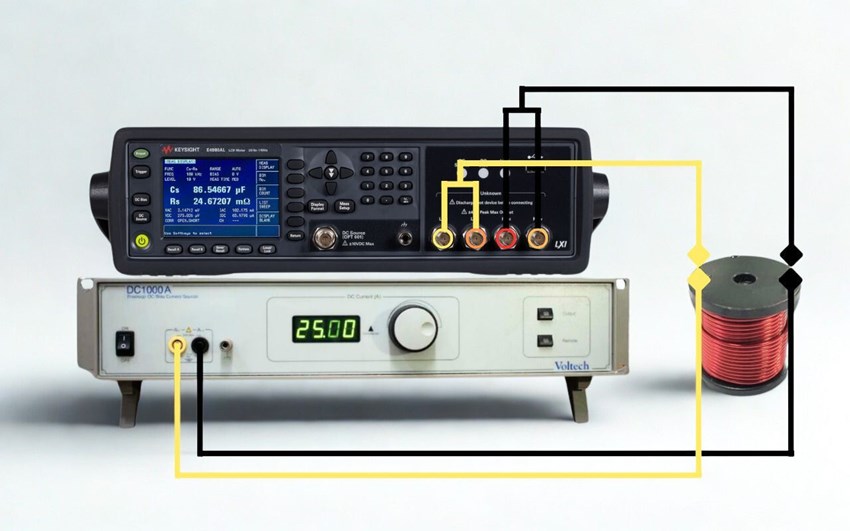

DC1000A + Any LCR Meter

The DC1000A is the only DC bias source that can be used with any LCR meter to measure inductance accurately under real DC bias conditions.

In this configuration, the LCR meter provides the AC test signal while the DC1000A supplies the required DC.

This allows the inductance of the device under test (DUT) to be measured accurately at different DC levels, without the errors normally caused by conventional power supplies.

The Voltech Advantage

Complete Solution: DC1000A + AT Series Tester

When used with a Voltech AT Series Tester (AT3600, AT5600, or AT7600) the DC1000A becomes a fully integrated DC bias solution for automated transformer and inductor testing.

In this configuration, the AT tester controls both the AC test parameters and the DC bias current, allowing all measurements, including inductance under load, to be performed in a single automated test program.

Unique Benefits:

- Real-time inductance vs. current plots

- Full automation and repeatability

- Calibration traceability and compliance

- R&D to production — one test platform

VI. DC1000A Key Features

|

Feature |

Specification |

|---|---|

|

DC Bias Output |

0–25 A per unit |

|

Current Accuracy |

±0.5% of reading ±25 mA |

|

Parallel Operation |

Up to 8 units (200 A total) |

|

Output Architecture |

Active constant-current configuration |

|

LCR Meter Compatibility |

Works with any LCR meter |

|

AT-Series Integration |

Fully software-controlled with AT system |

VII. Proven Results Across Applications

| Application Type | Typical Use |

|---|---|

| Power Inductors and Chokes | DC bias characterization |

| SMPS Magnetics | Load-condition validation |

| Automotive Inductors | Confirms performance under high current |

| Transformer Leakage and Inductance Studies | Pre-saturation behavior |

| High-Current Cores | Multi-unit DC bias testing |

VIII. Conclusion

Without a high-precision, purpose-built DC bias source, inductance cannot be measured under real operating conditions. Conventional bench supplies and improvised test methods all produce unreliable results, making accurate inductance testing extremely difficult, if not impossible.

The Voltech DC1000A changes that. It delivers a stable, highly precise DC bias current source engineered specifically for accurate inductance testing – with the accuracy required in R&D, the automation required in production, and full compatibility with both standalone LCR meters and Voltech AT-Series automated test systems.

See the Difference in Your Own Test Bench — Free 30-Day Trial

Since inductance behavior under DC Bias is design-specific, the most meaningful results come from testing your own components under your own conditions.

Voltech’s 30-day evaluation program for the DC1000A allows engineers to verify performance and experience the technology firsthand

✔ Zero Upfront Cost

✔ Full feature access

✔ Full support from Voltech engineers

Complete the Form below to request your free trial